What do you Need to Prepare for A Quotation

It’s fine!! You may not be a casting professional and don’t know much about molds and die casting. But circumstances come up where you need to prepare a quote. However, we are always ready to be of great help.

When you are ready to let us give a quote, it’s ideal to know that you will need to provide some information. So the question is, what information do you need to provide?

Not to worry, this piece will provide all the answers you need and get you out of confusion.

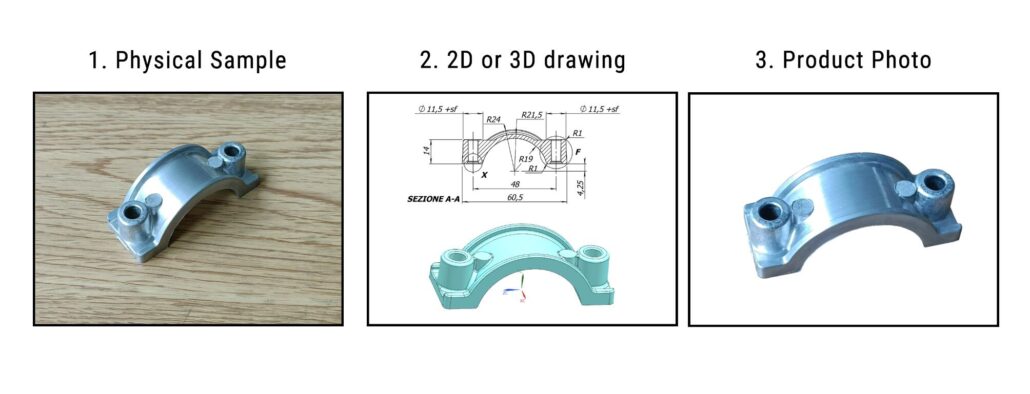

In a bid to answer your questions, we divide the available information into the following

- Physical samples

- 2D drawings and 3D drawings

- Product photos

Situation 1:

When you have all three kinds of information as seen above, please send us the product drawings and product photos. Our engineers will discuss, analyze, and give you a quotation within 24 hours. If you need us to produce products and make molds in the future, you can send samples to us.

If your previous product is defective, or there are many problems in the die casting process. You can report the issue to us. Then, when designing new molds and setting the die-casting production process, we will definitely consider and solve these problems.

Situation 2:

When you only have 2D drawings or 3D drawings but no samples. You can send us the drawing, and we will quote you according to the drawing and your requirements.

If there is any part of the product that is not conducive to the die-casting process, we will submit a DFM report before production.

Situation 3:

When you only have samples. We analyze this concept in three scopes:

1. If it is a simple product, just put the ruler aside and take pictures of different sides. Such as the following case.

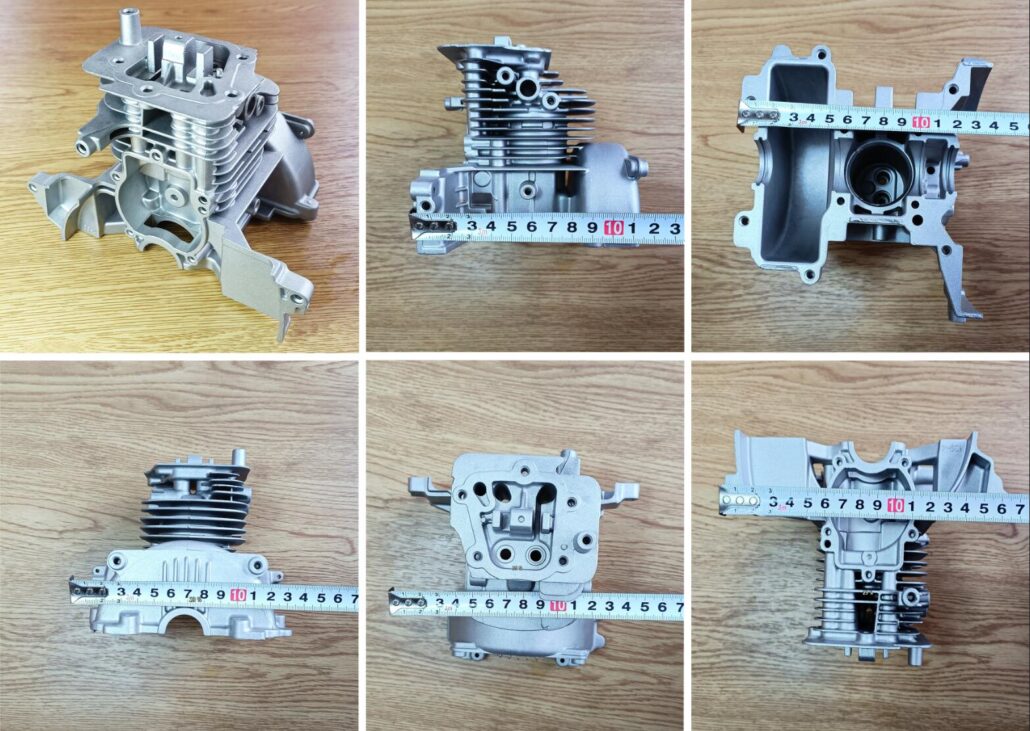

2.If a product structure is more complex, like this product, as shown in the figure. You may need to take photos from different directions and put the ruler aside. For example, if the product has shapes on all six sides, images need to be taken from all sides.

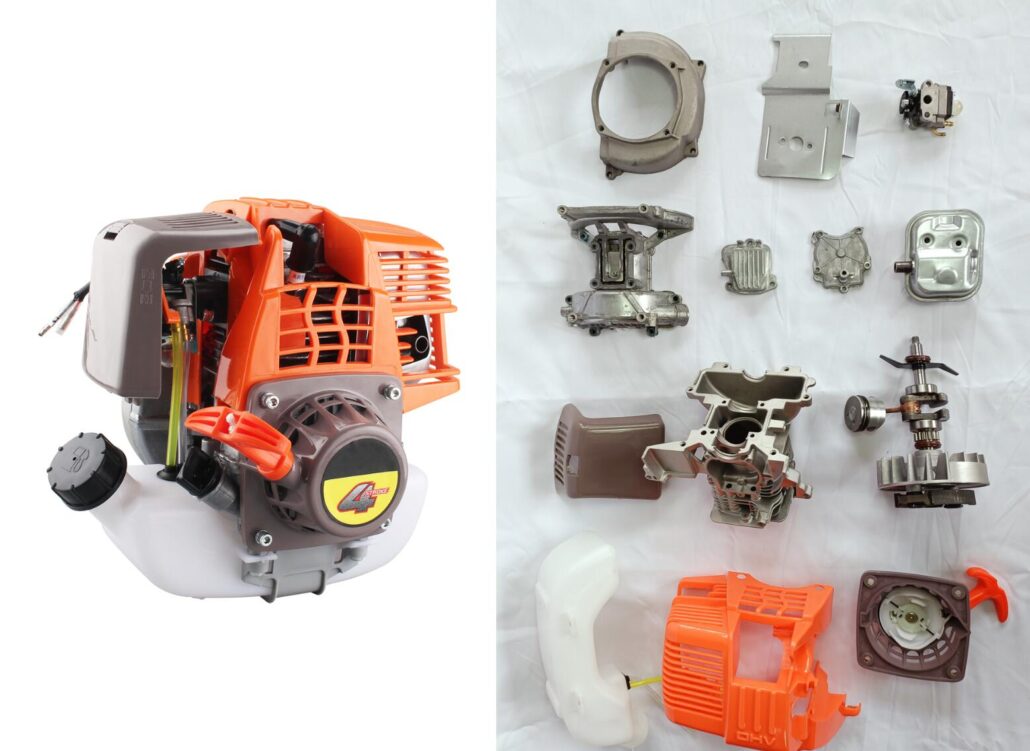

3.If your sample is a whole part or a small machine, like the picture below. Then you first need to dismantle them. After that, classify the die castings you need to make. Then take pictures of the die-casting parts you want to produce one by one. And check the weight of each product.

Before the formal production, it’s best to send samples to us. Then, we will use scanning technology to reconstruct the 3D model of the product. After you confirm that the drawings are correct, we will proceed to the next step of mold design.

Situation 4:

When you have no samples, no drawings, only a few photos of the product, please send us the picture and tell us the approximate size. For simple products, we can still estimate a price for you. However, for complex products, we need to buy a real sample before giving a quotation.

For some simple products, we can also design 3D models for you. But you need to have 3D design software and view the model we designed. Commonly used 3D design software includes UG, SolidWorks, CATIA, etc.

Situation 5:

When you have no samples, no drawings, no pictures, only a design concept, you don’t need a quotation at present. But you need to look at our knowledge about die casting design; we will continue to update it in the future.

In short, if you still have any questions, you are welcome to communicate with our engineers, and we will listen to your demands.