Mold & Tooling

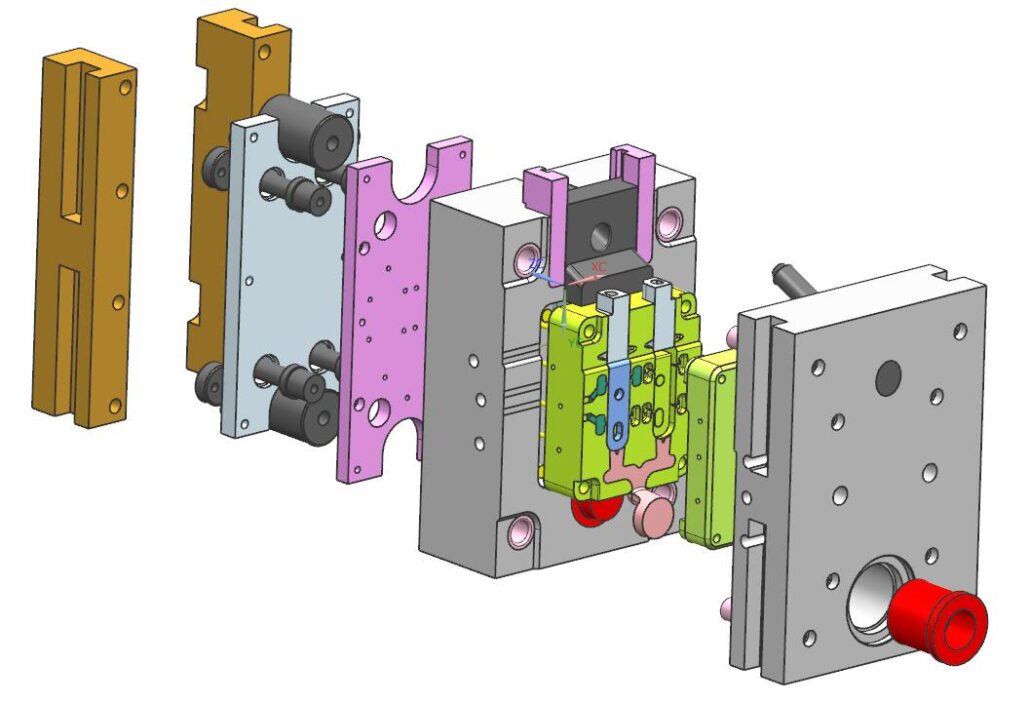

1 Brief Introduction Of Die Casting Mold Structure

Die-casting mold is the main process equipment for die-casting production and the carrier of die-casting. Whether the production process can be carried out smoothly and whether the casting quality is guaranteed depends largely on the rationality of the mold structure.

2 Mold Design - Mold Temperature Control

When discussing the entire concept of die-casting molds, we cannot neglect the aspect of temperature control. It is a vital aspect of the die-casting industry.

3 Die Casting Die Life and Failure Mode

The mold life is the maximum number of products that the mold can form under the condition of ensuring the output of qualified die castings.

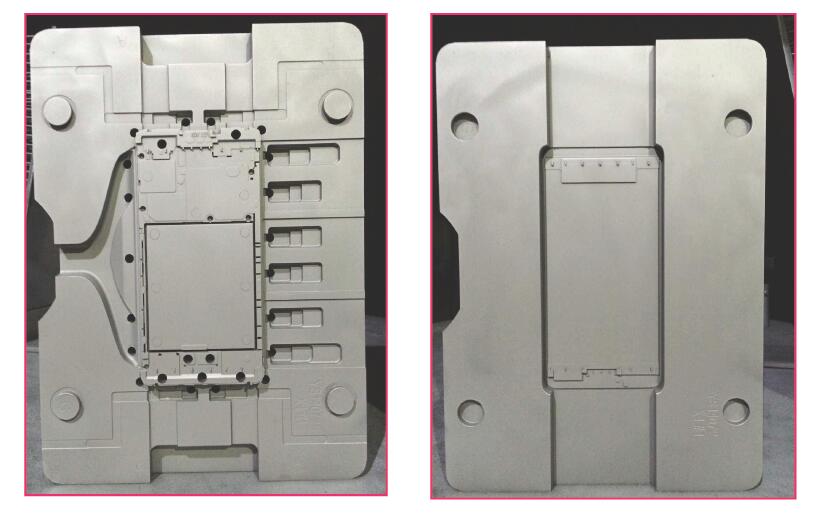

4 Performance Requirements of Mold Steel

Mold steel is a material that helps in fabricating the mold. As a result, it must be top-notch.

5 Mold Heat Treatment Process

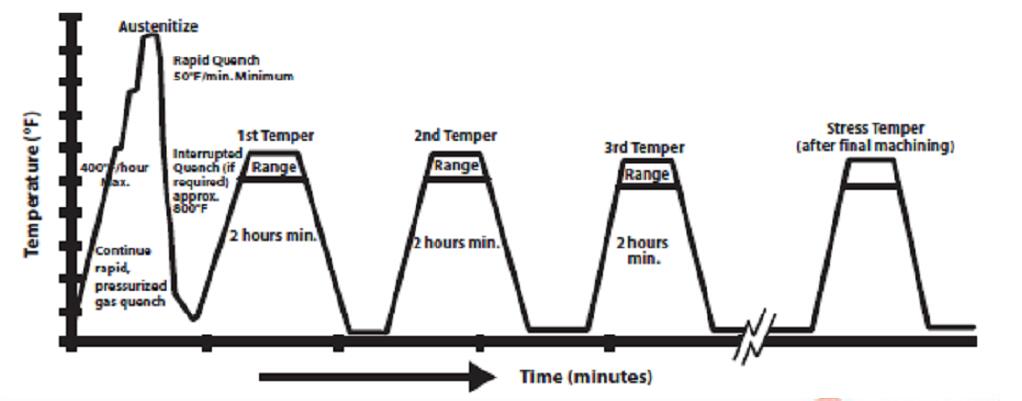

There are eight crucial sections for heat treatment process.

6 Heat Treatment Performance And Prevention Of Mold Failure

The most important parameters in heat treatment are austenitization and cooling rate. The cooling rate must be tightly controlled to reduce the risk of deformation and cracking while obtaining optimal metallurgical properties.

7 Extend Tool Life - Design Operation and Maintenance

- Points for attention in die casting design

- Points for attention in die-casting mold design

- Points for attention in the operation of the die casting process

- Mold maintenance

8 Extend Tool Life - New Technology

With the continuous development of the die-casting industry and the continuous improvement of die-casting technology, many new technologies have been applied to the mold, which can greatly extend the life of the mold.

9 Mold Surface Treatment Technology

Different surface strengthening technologies can effectively improve the mold surface’s wear resistance, corrosion resistance, adhesion resistance, and thermal fatigue resistance.

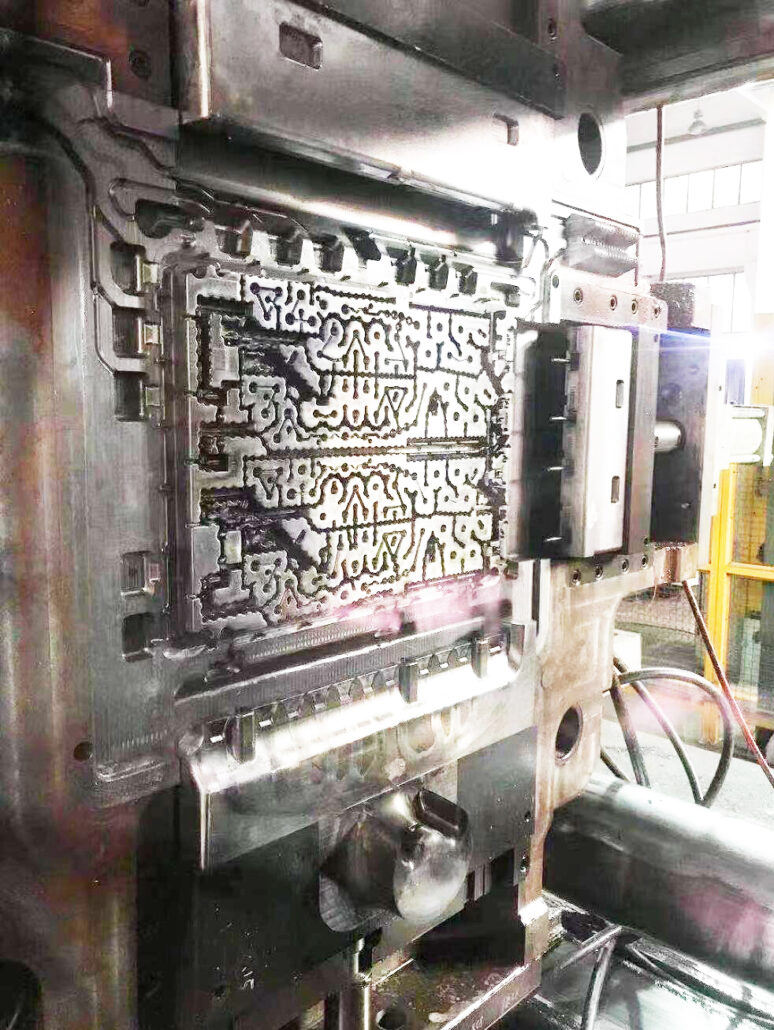

10 Die-casting Mold Maintenance

For the die-casting workshop, the good maintenance of the mold is a strong guarantee for the smooth progress of normal production, which is conducive to the stability of product quality.

11 PVD For Mold

PVD coating technology is currently the most widely used and most valuable type of surface treatment technology. Without affecting the original size of the workpiece, PVD coating can be used to improve surface appearance, improve surface strength, and enhance wear resistance.