Heat Treatment of Die Castings-2

We dealt with the first part of heat treatment of die castings. Now. It’s time to get more information concerning the same subject matter.

1.Die Casting Heat Treatment Process

Common state of aluminum alloy

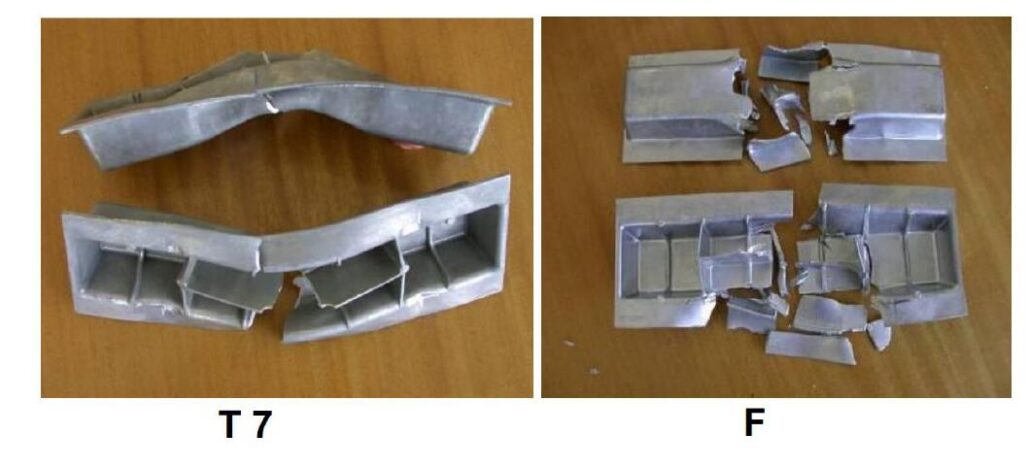

F state: free machining state or no heat treatment state. It is suitable for products that do not have special requirements for work hardening and heat treatment conditions during the molding process. In normal practice, we do not indicate the mechanical properties at this state.

O state: the annealed state. Suitable for processed products that have been fully annealed for minimum strength.

The annealing process includes homogenization annealing, stress relief annealing, and full annealing. Homogenization annealing treatment can eliminate the inhomogeneity of structure and composition in the ingot; stress relief annealing treatment can effectively eliminate the stress in the ingot and the hardening of the processed material; after complete annealing treatment, the material has low deformation resistance and high plasticity.

H state: work-hardened state. It is suitable for products whose strength is increased by work hardening, which may or may not be subjected to additional heat treatment to reduce the strength after work hardening.

W state: solution treated state. An unstable state, is only applicable to alloys that are naturally aged at room temperature after solution treatment. The W state code gives a pointer that the product is in the natural aging stage.

T-state: suitable for products that have been (or not) work-hardened to stabilize after heat treatment. One or more Arabic numerals must follow the T code. The first digit after the T character indicates the basic type of heat treatment (1-10), and the subsequent digits indicate changes in the heat treatment details.

Aluminum alloy heat treatment process - T1

T1 (cast aluminum alloy)

Alloy State: Artificial Aged

The role or purpose of heat treatment: the alloy cast in the metal mold or wet sand mold has obtained a certain degree of supersaturated solid solution due to the fast cooling rate; that is, there is a partial quenching effect. After artificial aging and desolvation strengthening, the hardness and mechanical strength can be improved, and the machinability can be improved.

T1 (deformed aluminum alloy)

Alloy state: high-temperature forming + natural aging

The function or purpose of heat treatment: it is suitable for cooling products, naturally aged after high-temperature forming, and is no longer subjected to cold working (or leveling and straightening that affect the limit of mechanical properties).

Aluminum alloy heat treatment process - T2

T2 (cast aluminum alloy)

Alloy Condition: Annealed

The role or purpose of heat treatment: the main role is to eliminate the internal stress of the casting (casting stress and stress caused by machining), stabilize the size of the casting, and spheroidize the Si crystal of the Al-Si alloy to improve its plasticity.

Description: The effect on Al-Si alloy is obvious, the annealing temperature is 280-300℃, and the holding time is 2-4h.

T2 (deformed aluminum alloy)

Alloy state: high-temperature forming + cold working + natural aging

The function or purpose of heat treatment: it is suitable for cooling after high-temperature forming, cold working (or leveling and straightening that affects the limit of mechanical properties) to improve strength, and then natural aging products

T3

T3 (deformed aluminum alloy)

Alloy state: solution + cold working + natural aging

The function or purpose of heat treatment: it is suitable for cold working (or leveling, straightening that affects the limit of mechanical properties) after solution heat treatment to improve strength, and then natural aging products

T4

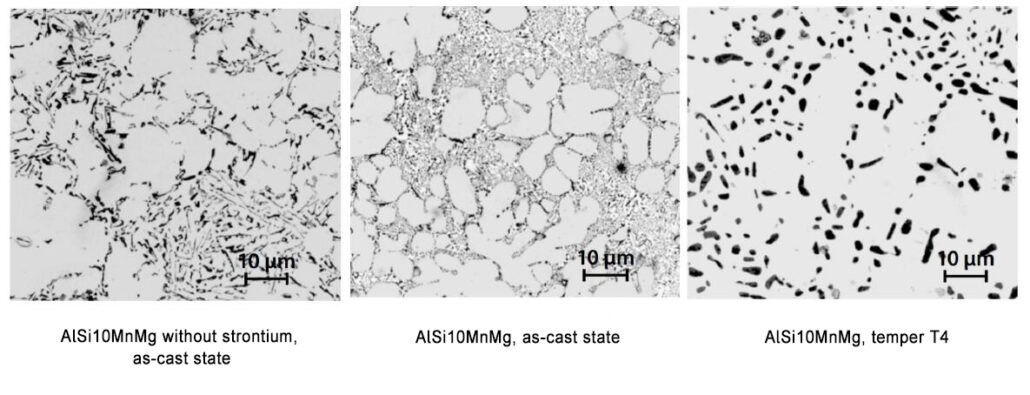

T4 heat treatment: The solution heat treatment is heated to 490~540 ℃, quenched directly in the solution heat treatment furnace, and natural aging treatment.

T4 (cast aluminum alloy)

Alloy state: solution treatment (quenching) → natural aging

The function or purpose of heat treatment: through heating and heat preservation, the soluble phase is dissolved, and then quenched, so that a large amount of strengthening phase is dissolved in the α solid solution to obtain a supersaturated solid solution to improve the hardness, strength and corrosion resistance of the alloy.

Note: The final heat treatment is used for Al-Mg alloys, and the preliminary heat treatment is used for other alloys that require artificial aging.

T4 (deformed aluminum alloy)

Alloy state: solution + natural aging

The function or purpose of heat treatment: it is suitable for products that are not subjected to cold working (or leveling or straightening that affects the limit of mechanical properties) after solution heat treatment and then naturally aged

T5

T5 Heat Treatment: The casting is immediately removed from the mold cavity and quenched with water. No solution heat-treatment process. Mechanical properties are poor compared to T6 treated castings.

Originally, semi-solid castings were often used, and now they are also applied to die castings and rarely used in squeeze casting.

T5 (cast aluminum alloy)

Alloy state: solid solution + incomplete artificial aging

The function or purpose of heat treatment is used to obtain higher strength and plasticity, but the corrosion resistance will decrease, especially the intergranular corrosion will increase.

Description: under-aging: the aging temperature is low, the holding time is short, the aging temperature is about 150-170 ℃, and the holding time is 3-5h.

T5 (deformed aluminum alloy)

Alloy state: high-temperature forming + artificial aging

The function or purpose of heat treatment: it is suitable for cooling after high-temperature forming, no cold working (or leveling and straightening that affects the limit of mechanical properties), and then artificial aging products

Description: under-aging: the aging temperature is low, the holding time is short, the aging temperature is about 150-170 ℃, and the holding time is 3-5h.

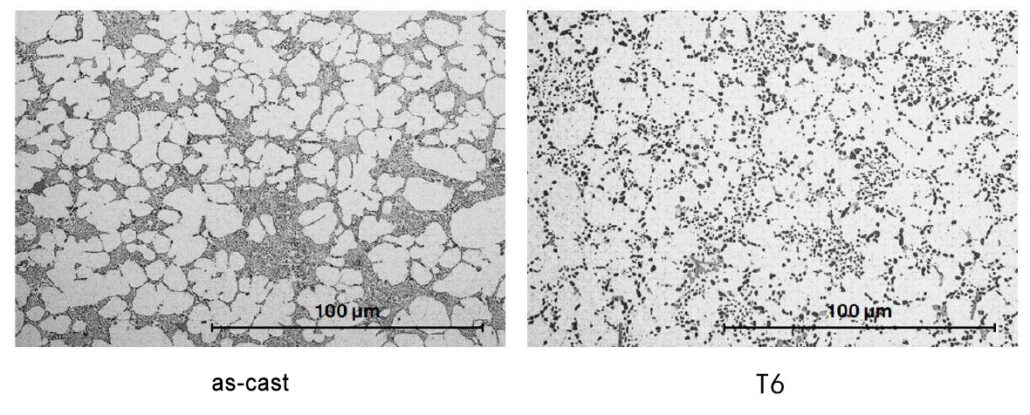

T6

T6 heat treatment, solution heat treatment is heated to 490~540 ℃ and quenched and cooled directly in the solution heat treatment furnace. Aging treatment is carried out at 150~200℃. Age at 150 to 200℃

T6 (cast aluminum alloy)

Alloy state: solution + fully artificial aging

The role or purpose of heat treatment is to obtain the highest strength, but the plasticity and corrosion resistance is reduced at higher temperatures and for longer periods of time.

Description: Complete aging is suitable for parts requiring high load, the aging temperature is about 175-185 ℃, and the holding time is more than 5h.

T6 (deformed aluminum alloy)

Alloy state: solution + artificial aging

The role or purpose of heat treatment: it is suitable for products that are not subjected to cold working (or leveling and straightening that affect the limit of mechanical properties) after solution heat treatment and then artificially aged

Description: Complete aging is suitable for parts requiring high load, the aging temperature is about 175-185 ℃, and the holding time is more than 5h.

T7

T7 heat treatment, solution heat treatment is heated to 490~540℃ and quenched directly in the solution heat treatment furnace, and the aging temperature is 200~250℃.

T7 (cast aluminum alloy)

Alloy state: solution + stabilized tempering

The function or purpose of heat treatment: it stabilizes the size and structure of the casting, improves corrosion resistance (stress corrosion resistance), and maintains high mechanical properties. Mostly at the working temperature close to the part.

Description: Over aging is suitable for parts that work at high temperatures below 300°C, the tempering temperature is 190-230°C, and the holding time is 4-9h.

T7 (deformed aluminum alloy)

Alloy state: solution + over aging

The function or purpose of heat treatment: it is suitable for over-aging to the stabilized state after solution heat treatment. In order to obtain some important characteristics other than the initial mechanical properties, the product whose strength has crossed the highest peak point on the aging curve during artificial aging

Description: Over aging is suitable for parts that work at a high temperature below 300°C, the tempering temperature is 190-230°C, and the holding time is 4-9h.

T8

T8 (cast aluminum alloy)

Alloy state: solution + softening and tempering

The function or purpose of heat treatment is to fully decompose the solid solution and aggregate and spheroidize the precipitated strengthening phase to stabilize the size of the casting and enhance the plasticity of the alloy. However, the tensile strength tends to decrease.

Description: It is suitable for castings requiring high plasticity. The tempering temperature is about 230-330°C, and the holding time is 3-6h.

T8 (deformed aluminum alloy)

Alloy state: solution heat treatment + cold working + artificial aging

The function or purpose of heat treatment: it is suitable for products that are subjected to cold working (or leveling or straightening that affects the limit of mechanical properties) to improve strength after solution heat treatment and then artificially aged.

T9

T9 (loop processing)

Alloy state: solution + softening and tempering

The role or purpose of heat treatment: to further stabilize the size and shape of the casting. The temperature and number of cycles of repeated heating and cooling are determined according to the working conditions of the parts and the properties of the alloy.

Description: It is suitable for parts that require very precise and stable size and shape.

T9 (deformed aluminum alloy)

Alloy state: solution heat treatment + artificial aging + cold working

The role or purpose of heat treatment: it is suitable for products that are subjected to solution heat treatment, artificial aging, and then cold working (or leveling and straightening that affect the limit of mechanical properties) to improve strength

T10

T10 (high-temperature forming + cold working + artificial aging)

Alloy state: solution heat treatment + artificial aging + cold working

The function or purpose of heat treatment: suitable for cooling after high-temperature forming, cold working (or leveling, straightening that affects the limit of mechanical properties) to improve strength, and then artificially aged products

Remarks:

Some 6XXX series or 7XXX series aluminum alloys can achieve the same solution heat treatment effect, whether it is solution heat treatment in the furnace or quenched after high temperature forming to retain the soluble components in the solid solution.

The T3, T4 of these alloys, T6, T7, T8, T9 state, can use either of the above two treatment methods, but the mechanical properties and other properties (such as corrosion resistance) of the product should be guaranteed.

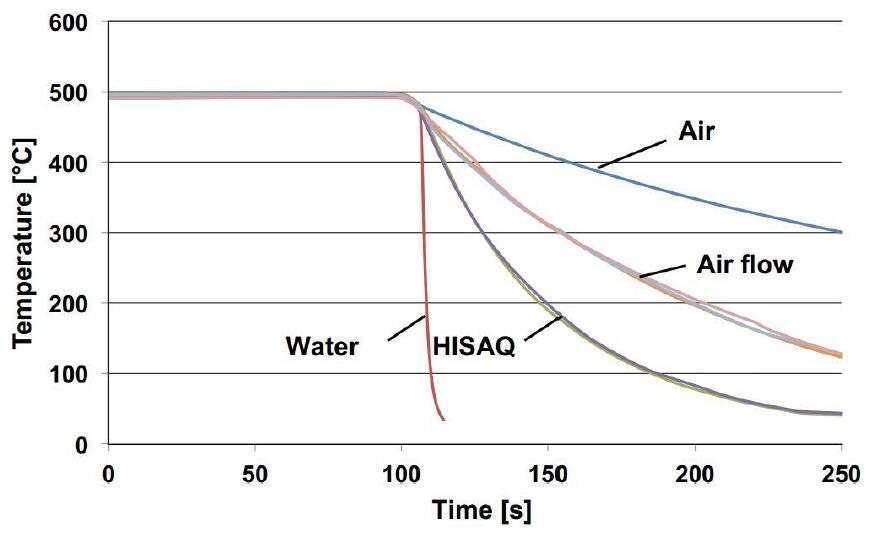

Solution quenching is shown in Fig.